Fuel Line

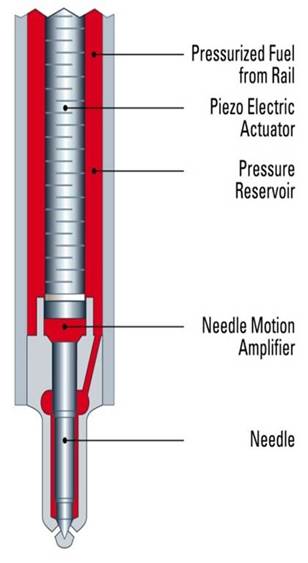

Piezo Fuel Injectors (CRI4)Manufacturers of the latest common rail engines are relying on piezo-powered fuel injectors. The pressure to reduce emissions of diesel engines is growing. One way to achieve this is to make the combustion of the fuel within the cylinder more efficient. Injecting fuel in smaller volumes, more frequently and more highly atomised produces less unburned fuel and, in turn, a cleaner burn with less emissions. Piezo fuel injectors (CRI4), which use piezo crystals as part of a rapid actuator, are helping manufacturers to meet their Euro 6 target. These injectors work by passing electrical current through a stack of Piezo crystals, causing them to expand; as the crystal discharges the current it contracts to the original size. The expansion and contraction of the crystals displaces the fuel within the injector, causing the needle valve to open and close extremely quickly. Firing the injector in this way delivers fuel into the combustion chamber up to five times faster than conventional electrohydraulic solenoid injectors. Because the piezo injector is faster, it can carry out more injections per cylinder stroke and allows for higher fuel system pressures; this improves the atomisation of the diesel, gives improved spray momentum and greater accuracy. The results are improved combustion control, less fuel wastage, a considerable reduction in emissions, more torque and power and better fuel economy. Cross Section of a Piezo Injector (CRI4)

Common Repair & Replacement Issues As with all common rail system components these injectors are manufactured to very fine tolerances. Failures commonly come about due to mis-fueling or high water content in the fuel (through lack of servicing or contamination within the fuel system). Remember, common rail injectors work in a hostile environment where they are subject to high temperatures (up to 350°C), having to deliver fuel to the combustion chamber accurately, quickly and at extremely high pressures, whilst also being the sealing point between the combustion chamber and the atmosphere. In some cases combustion blow-by past the injector from the combustion chamber can occur. This leaves carbon deposits between the injector and cylinder head which often requires specialist tools for removal of the injectors. Thorough cleaning of the injector aperture and seal seats, the use of high quality seals along with the correct tightening torque when installing the new/remanufactured injectors can help to prevent these types of problems in the future. Piezo injectors have been utilized by some of the major motor manufacturers, with the Renault 2.0 dCi engine being a popular application. However, this does not spell the end for the solenoid injector as equipment manufacturers are now finding ways to make solenoids produce similar results to piezo technology.

A Word of Caution Piezo diagnosis can be dangerous as the injectors operate at up to 200 volts and 15 amps. If disconnected while the piezo crystals are expanding they will not be able to ground and the injector will remain in the expanded state. Therefore, no attempt should ever be made to disconnect these injectors while the engine is running. After only a few engine revolutions enough fuel will have entered the cylinder to cause hydraulic lock and serious engine damage, not to mention the risk of electric shock. *Euro numbers explained All new cars have to meet ‘Euro’ standards, which set limits for emissions like particulates (soot) and NOx (nitrogen oxides). Current legislation, Euro 5, has reduced the particulate emissions of diesel engines to levels similar to petrol vehicles. From September 2015, all new cars had to meet Euro 6. This reduces diesel cars’ NOx emissions, making them almost as clean as petrol cars in terms of pollutants. |

Related Articles Related Downloads |