Interior

Seatbelt SafetySeat belts are a safety critical part whose importance should not be overlooked. Securon explain why quality is key. Every year over 400,000 vehicles fail their MOT due to the seat belts, so there’s a big opportunity waiting for factors who stock belts.

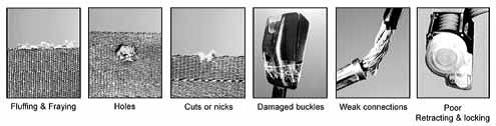

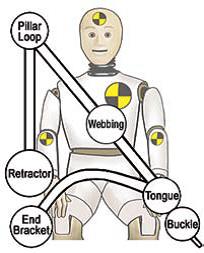

System Components The average passenger car requires 5 seat belts. Key components within the seat belt system include: Seat belt webbing is woven from thousands of strands of polyester. The impact in an accident reduces the effectiveness of the belt because it permanently elongates the webbing – by as much as 13%. If the belt is not replaced following this elongation, the wearer’s body would take the full shock load in subsequent accidents -approximately equal to the weight of a three tonne elephant against the belt. Many modern cars incorporate a Seat Belt Reminder (SBR) system. A pressure sensor in the seat is connected to the belt buckle and alerts the driver via an audio-visual alarm when the seat’s occupant hasn’t fastened their belt. Seat belt wearing in cars fitted with SBR is approx 97.5% compared to 85.8% in cars without. Quality is Key Securon replacement belts are manufactured and tested to the same European Standards as the original belts. European Standards go far beyond the scope of the MOT test so when a Securon belt is fitted, customers can be assured that they are in safe hands. Seat belts save lives and reduce injuries if they are in good condition, if not their performance is dramatically affected. When a belt or harness shows signs of wear and tear or abuse the complete system must be replaced. Seat Belts are non-serviceable safety products so no attempt should ever be made to alter, disassemble or repair them as even minor alterations can affect the validity of a belt. Innovation Securon believes it is the only manufacturer able to provide an ‘E’ approved lap and diagonal seat belt for installation in the centre rear of cars. The belt uses the anchorage points of the lap belt with one additional fabricated anchorage point. This means the integrity of the lap belt is maintained and additional safety is provided by the diagonal belt.

Important Dates in the UK Car Seat Belt History 1967 – New Cars must be fitted with front seat belts 1969 – Seat belts first included in the MOT Test 1977 – MOT Test includes all front seat belts 1983 – Compulsory to wear front seat belts 1987 – New card must be fitted with rear seat belts 1989 – rear seat belts, if fitted must be worn by children under 14 1991 – MOT Test includes all rear seat belts 1991 – Rear seat belts, if fitted must be worn by adults 1998 – Every seat belt fitted to a car is included in the MOT Test

Securon belts are manufactured and carefully tested to European Standards before they can be fitted to motor vehicles, below shows some of the key features are tested as part of the European Standards: Does it Lock? – Retracting belts must sense an accident situation and lock Does it Retract? – Requires a minimum retraction force to prevent slack in the belt system – slack permits body movement which can result in serious injury Is in User Friendly? – The buckle must disengage when lightly pressing the release so there is no doubt whether the belt is connected or not Is it Approved? Belts must be clearly marked to show the type of belt, approval and approval authority. This ensures only belts of the relevant standard and quality are fitted. Has it been Used? Some belts are fitted with pretensioner which takes slack out of the system in an accident.

|

Related Articles |