Cooling

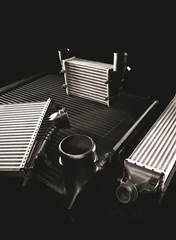

Cool Runnings with NissensModern-day engines are put through an enormous strain, meaning the cooling system has become an integral element in vehicle performance. Cooling systems can be a cause of roadside breakdowns, making it important for motor factors to know the parts that their customers may need. Nissens offers some key information on intercoolers which are becoming increasingly popular within the independent aftermarket. FUNCTION Turbocharged engines are prevalent through both the popularity in diesel technology and newer turbo-charged smaller petrol engines, which means most of the modern diesel and many petrol engines are equipped with an intercooler. The intercooler is an air-to-air heat exchanger that significantly improves the combustion process. As the vehicle moves, warm air from the turbo is forced through the intercooler’s internal core and the cool air drawn through the fins into it, producing a cooler air circulation and in turn, enabling more engine power. As the intercooler reduces the temperature of the hot air compressed by the turbo prior to it entering the combustion chamber, it has an impact on the charge effect, as the cooled air has a much higher density (more air molecules per cubic cm). The result: a marked increase in air intake and a much improved engine output. Benefits of having intercoolers in turbo-charged engines: · increased engine power and efficiency · lower fuel consumption, leading to better fuel economy · lower engine emission values, meaning less pollution · lower thermal stress on the engine and its components COMMON FAULTS A damaged or malfunctioning intercooler can lead to serious damage of the turbocharger, engine or the exhaust filters (DPF for diesel engines and catalysts for petrol engines). Symptoms: · Noticeable drop in engine power: caused by improper pressure in the turbo-charge system and incorrect ratio of oxygen in the fuel/air mixture · Increased fuel consumption: due to loss of oxygen · Unnatural smoke from the exhaust system: triggered by a surplus of fuel that cannot be combusted and is consequently emitted from the exhaust system Causes and consequences of failure: · Frontal accidents and stones/particles thrown from the road can cause physical, external damage, causing leaks. · Intercooler tubes clogged by oil, particles or damaged turbo parts reduce the internal air flow and cause turbocharger failure. · Improper sealing of the turbo unit causes clogging and the oil blown into the intercooler quickly damages the rubber gaskets, leading to leakages between the core and tanks or even ‘blown tanks’. · Soiled surface of the intercooler reduces the air flow and thus the cooling performance of the unit. REPLACEMENT The intercooler should always be replaced when installing a new turbocharger. In the event of turbo failure, oil from the charger as well as swarf from its damaged parts can be sent through the entire system and may clog the intercooler channels. When a new turbocharger has been installed, the system will operate with high pressure and both the oil and the particles collected in the intercooler risk being instantly blown into the combustion chamber, possibly damaging the engine. All system components must therefore be thoroughly examined before installation to ensure there are no oil blockages or swarf residues. Nissens’ current range offers 360 part numbers and is expected to grow to over 400 by the beginning of 2017. |

Related Articles Related Downloads |