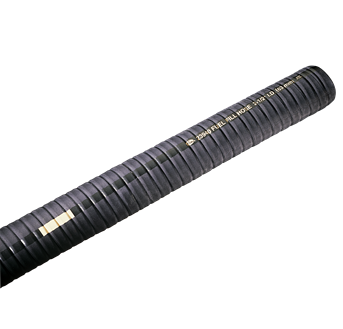

Fuel Line

Fuel Hose SelectionAutomotive hoses are specialised components, designed to cope with the combined stresses of intense heat, advances in fuel system technology and fuel formulations that can quickly degrade unsuitable and inferior hose materials. Diesel, biodiesel and the wide range of ethanol and methanol-based petrol fuel alternatives all have different chemical compositions. They have individual performance characteristics that make some fuels more corrosive than others. Advances in Electronic Fuel Injection (EFI) have increased operating pressures and enhanced the destructive effect on fuel hose materials.

Emerging technology Traditional hoses cannot handle some of these fuel types, so news of a new generation of replacement fuel hose is very welcome. Gates’ Barricade® Fuel Injection Hose can be used in any fuel injection application, offering a single solution to a range of fuel hose replacement problems. With a high resistance to the corrosive power of E15 (a blend of 15% ethanol and 85% petrol) it is not affected by the increasing diversity of fuel types. It also prevents vapour permeation through the hose wall. The key to its success is its five-layer barrier technology:

Fuel hose selection and replacement

The ten common reasons for fuel hose assembly failures include:

For every replacement job, there is a matching fuel hose in Gates' range that provides dependable and safe service. Gates small diameter multi-purpose hose, with working pressure up to 1 MPa, is recommended for clamped hose applications on all fuel systems except biodiesel. The textile covered fuel line hose, a small-diameter hose with a durable and oil resistant textile cover, comes in seven different sizes and has a working pressure up to 0.6 MPa. Special fuel hoses, with very small-diameters and which are suitable for use as connection and vacuum hoses, are also available. A further five sizes are available for installation as flexible hoses for connection between the vehicle’s filler neck and fuel tank. The Barricade® Fuel Injection Hose is approved for use on all fuel injection applications and is introduced with immediate coverage for all fuel systems. |

Related Articles Related Downloads |

.png) Since 1st January, 2011 fuel formulations at the pumps have changed. The Fuel Quality Directive (Directive 2009/30/EC) states that 10% of fuel consumption in transport should come from renewable sources by 2020. As a result, drivers will find that the main grades of unleaded petrol will contain up to 10% ethanol (or a mixture of limited ‘oxygenates’ up to an equivalent 10% limit), while diesel will contain up to 7% FAME (Fatty Acid Methyl Ester).

Since 1st January, 2011 fuel formulations at the pumps have changed. The Fuel Quality Directive (Directive 2009/30/EC) states that 10% of fuel consumption in transport should come from renewable sources by 2020. As a result, drivers will find that the main grades of unleaded petrol will contain up to 10% ethanol (or a mixture of limited ‘oxygenates’ up to an equivalent 10% limit), while diesel will contain up to 7% FAME (Fatty Acid Methyl Ester)..png) It is clear, then, that all fuel hoses are not the same. Each hose is designed to perform under particular sets of circumstances and to match OE specifications. Installers encounter a range of fuel hose installation problems, and fitment of an inappropriate hose risks altering the design of the vehicle’s fuel system. If an engine fails as a result, the repairer may be liable for an expensive repair job.

It is clear, then, that all fuel hoses are not the same. Each hose is designed to perform under particular sets of circumstances and to match OE specifications. Installers encounter a range of fuel hose installation problems, and fitment of an inappropriate hose risks altering the design of the vehicle’s fuel system. If an engine fails as a result, the repairer may be liable for an expensive repair job.