User Contributions

We want to hear from you!

In order to provide the most practical and helpful resource available we want to hear from you with any automotive related technical hints, tips or articles that you think are newsworthy and would help other installers and professionals within the industry.

The hint, tip or article could be relating to a common installation problem or difficulty (and its solution), general installation/maintenance tips regarding a specific product/system or a new technology or product that you have heard about or come across.

In return, each month we will select a 'star contributor' in recognition of the person that provides the most high quality, publishable content. Star contributors will receive an Amazon e-mail voucher of £10 in value.

Braking

Contributor : Stuart Johnson, Blue Man Autoparts

Vauxhall Insignia - supplying front braking

We've had numerous issues before when supplying front brake discs and pads to customers with Vauxhall Insignias - there are three different sizes of disc, and they are catalogued as being for 16", 17" and 18" wheels. We ask the customer the question, "what size wheels has it got?", but invariably we then get contacted by the customer informing us we've supplied the wrong size discs.

The problem appears to be that although, for example, a vehicle can leave the factory with the 16" braking system installed, often while at the dealer, the wheels are 'upgraded' to the larger size, at the customer's request. So although an Insignia may have 17" wheels, it could have the 16" braking system. To avoid supplying the wrong discs, rather than ask the question of what size wheels are on the vehicle, it is more worthwhile to ask the customer to just measure the size of the discs themselves.

Ignition

Contributor: Andy Sparks, K-Town Motors

VAG Pencil Coils - Ignition Lead Repair Kit

We recently had an issue with a VW Polo pencil coil replacement - we replaced one of the coils after having identified that the original had developed a fault, however a couple of days later our customer returned explaining that the engine was still stalling.

Following a call to the Cambiare technical hotline and some further investigation we identified that the pencil coil connector lead also needed replacing as the original had a couple of loose pins in the connector piece. Since replacing the connector the customer has not experienced any further problems. I would recommend that it is good practice to check these connectors whenever a coil of this type is to be replaced. This ignition lead repair kit is available from Cambiare under part number VE520313.

Steering

Contributor: Stuart, General Traffic (Bolton)

VW Polo, Steering Pump Failure

Following a recent power steering pump failure on a VW Polo 02-09 shape, a genuine TRW pump was purchased (JER104) and this did not fully cure the problem. Due to this pump being electric it is fed via the alternator, so the customer was advised to test the alternator and it was faulty!

So, in future if you are servicing a vehicle with an electrical power steering failure check the alternator first!

Switches & Sensors

Contributor: Mark Broughton, Total Motor Factors Ltd

Vauxhall Corsa 2000>, Oil Pressure Switch Failures

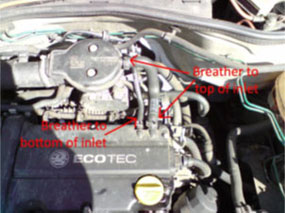

There are two breather pipes that come from the cam casing on the Vauxhall Corsa 2000>, engine codes Z10XE and Z12XE - one goes to the top of the inlet, above the butterfly valve and one goes to the bottom of the inlet, underneath the butterfly valve. You cannot see where it goes underneath the throttle body without removing the top of the inlet from the top view, and it's a bit difficult to as it is at an odd angle.

Pressure can build up in the cam casing, and the larger breather pipe allows this pressure to escape to the top of the inlet, and so only allows the pressure through when the butterfly valve is open. It is larger because the majority of the time the valve is open. When the valve is closed, pressure cannot escape through the larger breather, so it must escape through the smaller breather, which goes underneath the butterfly valve, and into the inlet manifold. If this pipe becomes blocked, pressure cannot be released and as a result pressure builds up in the cam casing. This pressure needs to go somewhere, and the easiest place for it to escape from is the pressure switch. So the pressure blows the pressure switch, and the pressure causes the oil to drip or even spray out.

Pressure can build up in the cam casing, and the larger breather pipe allows this pressure to escape to the top of the inlet, and so only allows the pressure through when the butterfly valve is open. It is larger because the majority of the time the valve is open. When the valve is closed, pressure cannot escape through the larger breather, so it must escape through the smaller breather, which goes underneath the butterfly valve, and into the inlet manifold. If this pipe becomes blocked, pressure cannot be released and as a result pressure builds up in the cam casing. This pressure needs to go somewhere, and the easiest place for it to escape from is the pressure switch. So the pressure blows the pressure switch, and the pressure causes the oil to drip or even spray out.

Regular servicing and using correct oil can help to reduce the build-up of contaminants and therefore blockages within the pipes. The pipes should also be removed and 'flushed through' to prevent the new switch failing. The replacement switch does not fail immediately as once the switch is removed, it obviously releases the built-up pressure. Correct maintenance as outlined above can help to optimise the lifetime of the new switch.

Top End

Contributor: Paul Robbie, Paul Robbie Motor Services

Mercedes SLK200 - Misfiring

We recently had an issue with a 2008 Mercedes SLK200 Kompressor, 1.8 petrol, with a misfire on cylinder 3. After testing the coil, spark plugs and fuel injector for correct operation, and smoke testing the inlet manifold for air leaks, we carried out a compression test and found that cylinder 3 was low in comparison to the remaining 3 cylinders.

We recently had an issue with a 2008 Mercedes SLK200 Kompressor, 1.8 petrol, with a misfire on cylinder 3. After testing the coil, spark plugs and fuel injector for correct operation, and smoke testing the inlet manifold for air leaks, we carried out a compression test and found that cylinder 3 was low in comparison to the remaining 3 cylinders.

After a bit of research it appears that these engines are prone to 'sticking valves' and the main dealer advice was to renew the cylinder head with a revised item at significant cost. We removed the head and found a good machine shop that manufactured new valve guides, fitted 2 new exhaust valve seats (offending cylinder 3) and decoked and skimmed the head. The outcome was a sweet running car at a considerable cost saving over a new head. Part Info adds that when replacing valve components after a misfire, the valve heads seating areas should also be checked as they may have suffered damage as a result of the misfiring - if there is any evidence of heat or any other damage, the valves should also be replaced.

Transmission

Contributor: Paul Knight, PSK Auto Repairs

Refitting the Gearbox - BMW 3 Series (E36)

It is possible when you refit the gearbox on the above model to dislodge the starter motor. If this does happen you will need to refit the starter motor which can be an awkward, time consuming job because of it's location under the inlet manifold.

This can be avoided by thoroughly cleaning and lightly lubricating the starter motor locating dowel found at the top of the gearbox bell housing.