Suspension

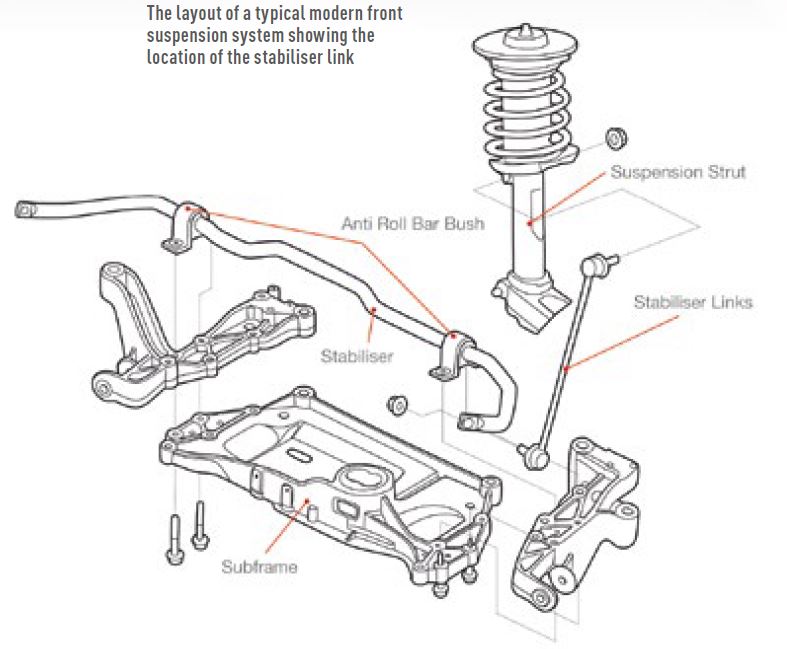

Anti-roll StabilityFebi sheds some light on the underrated stabiliser bar and some key failure symptoms to look out for. Connecting the wheel suspension of an axle with the body structure, the stabiliser bar (or anti-roll bar) plays a major role in ensuring the safety and comfort of a car journey. They have been installed in passenger cars for many decades and the design has practically remained unchanged. While many cars are equipped with a stabiliser bar on the front axle, some applications feature them in the rear axle as well. PART OF A WORKING SYSTEM Part of the stabiliser system that comprises other components like the links and bearings, the stabiliser bar is mostly mounted on a subframe and in rubber bearings. The stabiliser links connect the bar to the suspension struts or the control arms. Special ball joints on the stabiliser links ensure the necessary freedom of movement to allow the stabiliser bar to do its job flawlessly. When a wheel deflects, the torsion of the stabiliser bar ensures that the other wheel is also raised and lowered on rebound. This prevents excessive rolling (lateral tilting) of the body when cornering. If two wheels deflect simultaneously, the stabiliser bar does not activate.

KNOCK-ON EFFECT Loud knocking noises that frequently occur in the suspension when driving over uneven terrain is often a warning sign of failure or damage to the stability system. These are most often caused by worn bearings or defective ball joints on the stabiliser links. Worn bearings cause the stabiliser bar to rattle on deflection and rebound. A frequently installed type of stabiliser link features ball joints that are protected by a rubber boot from water ingress and contaminants. Packed with grease to make movement as frictionless as possible, the rubber boot or the associated seal can be damaged. When this occurs, the excess water ingress can cause unnaturally high wear where the key symptom manifested is a knocking sound. Failure of, or damage to, the stabiliser bar is mostly inexpensive to fix. This is due to the relatively low material costs, and straightforward installation. However, if the stabiliser bar is damaged, the vehicle should not be moved. A failing or damaged stabiliser bar can heighten the risk of uncontrolled rolling of the vehicle body – increasing the risk of the vehicle overturning. REPLACE IT RIGHT When replacing a stabiliser link, the installer should always ensure that the correct torque is applied during installation. Failing to do so can damage the ball joint, causing premature wear and breakage. |

Related Articles Related Downloads |