Federal-Mogul explains how its technical partnerships with vehicle manufacturers are helping to reduce CO2 emissions and reduce fuel consumption.

Federal-Mogul’s latest technologies are developed for OEMs to meet today’s emissions and economy challenges. These technologies can be broadly classified as either direct solutions or enabling solutions. A direct solution makes an immediate, direct improvement such as reducing friction or cutting component weight. Enabling solutions help designers to implement new engine strategies reliably, such as allowing the use of turbocharging to increase efficiency.

Many of these technologies lead engine designers towards downsizing, creating smaller engines that produce more power per litre, burn fuel more efficiently and have lower frictional losses. Specifying the right components, from new and during repair, has never been more critical to ensure long service life.

Three recent Federal-Mogul product groups embody the changing technologies within the modern engine: IROX® bearings and DuraBowl® pistons are examples of enabling solutions, while LKZ-Rings® are a direct solution.

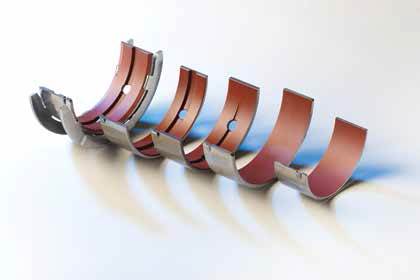

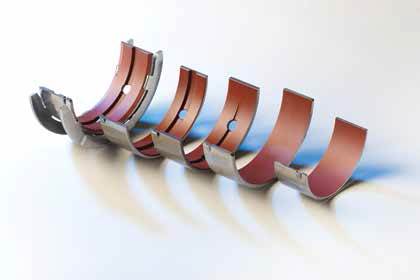

Glyco® IROX Bearings

IROX bearing technology addresses the lubrication challenges arising from the increased engine restarts of stop-start and hybrid engines, as well as the increased mechanical loads produced by heavily-boosted downsized engines and the thinner oil films generated by today’s lower viscosity oils.

It can increase the life of crankshaft surfaces and bearing shells by more than five times in the most demanding applications, and reduces friction by up to 50% compared to metallic sliding layers.

IROX is a polymer coating on the bearing shell that can withstand momentary operation without lubrication and can also carry the very high loads imposed by highly boosted engines. As well as increased impact absorption and wear resistance, it provides high thermal conductivity to keep the bearing cool.

DuraBowl Pistons

By re-melting the alloy around the rim of the bowl, the silicon particles can be reduced to only one tenth of their LKZ-Rings

previous size, substantially increasing the strength and durability of the piston rim. The DuraBowl piston uses this technique to increase the service life to between four and seven times that of a conventional cast piston.

LKZ-Rings

LKZ-Rings

Federal-Mogul’s 2011 PACE Award-winning Goetze® LKZ-Ring is a two-piece design originally developed for highly demanding diesel applications and now also optimised for direct-injection petrol engines. Compared with conventional two-piece rings, the LKZ-ring reduces oil consumption by up to 50% and friction by up to 15%.

The key to the new ring’s oil control is a “stepped” surface and taper on its contacting edge. Conventional piston rings apply equal pressure to the cylinder bore on both the up and down strokes. LKZ-rings provide the required pressure to the cylinder wall on the down stroke but significantly less on the upstroke. This reduces frictional losses while more effectively returning oil to the oil pan rather than allowing it to enter the combustion chamber.

.

LKZ-Rings

LKZ-Rings