Top End

Interpreting Variable Valve TechnologyThe Ins and Outs of variable valve timing (VVT) and variable valve lift (VVL)

MECHANISM

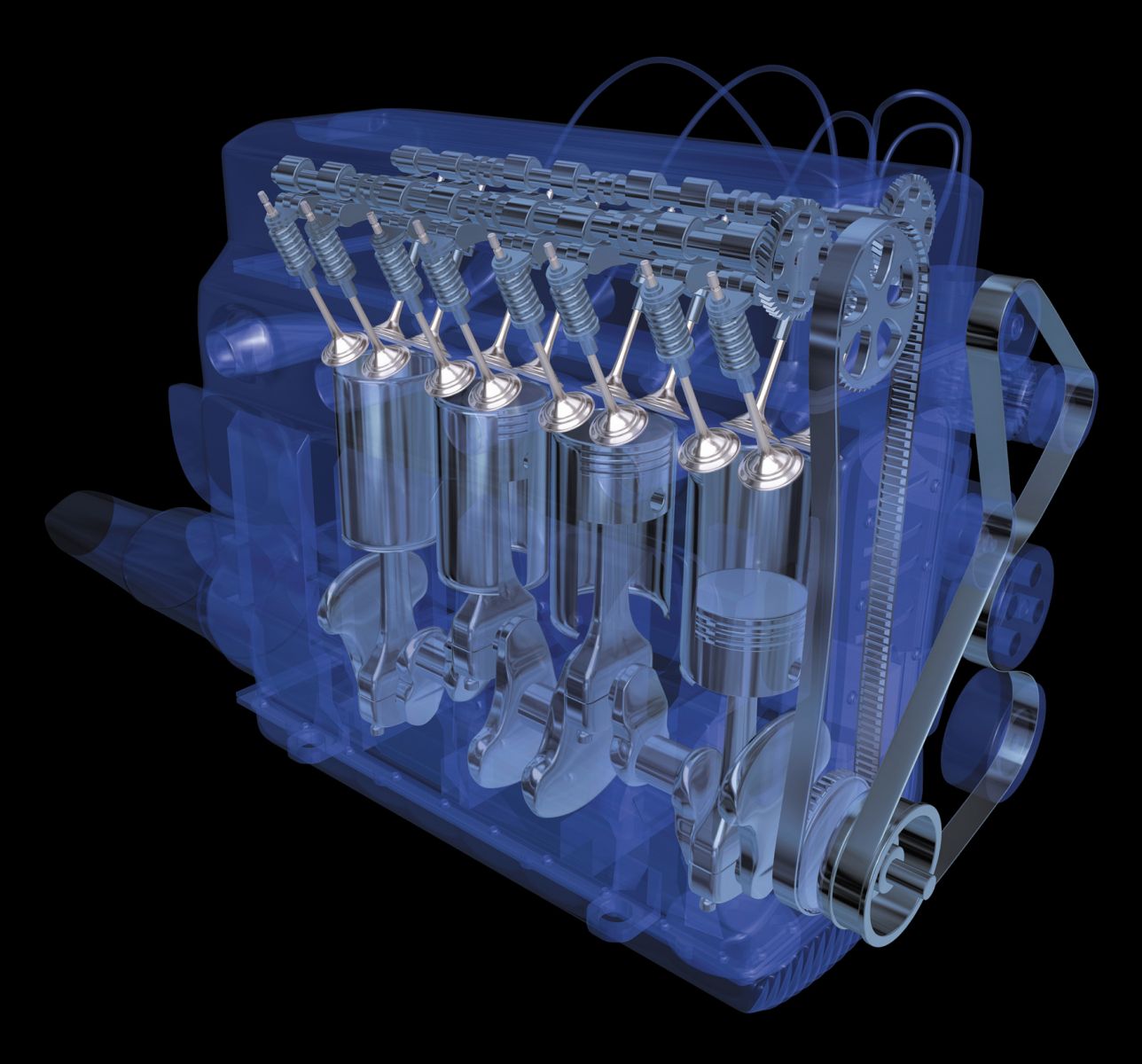

The valves in an engine operated by a camshaft open and close to allow:

1. Intake of fresh fuel/air mixture into the engine

2. Ejection of combusted gas from the engine into the exhaust

With a lot of engines, these actions occur at fixed specific intervals of the engine stroke, meaning the valves open and close at the same point in relation to the crankshaft position throughout the complete RPM range of an engine. This can have limitations in emissions control, performance and efficiency as the optimum valve timing at low engine RPM will differ from that at high engine RPM.

Some vehicle manufacturers now incorporate variable valve systems to maximise performance, economy and emission control. Variable valve timing (VVT) and variable valve lift (VVL) are both systems used in engines to vary the timing and duration of the opening and closing of the valves in relation to the crankshaft position. Simply put, the valve events can be suited to engine speeds and loads.

VARIABLE VALVE TIMING (VVT)

This system can vary when the valves open and close but does not influence the duration. This is achieved by numerous methods, most commonly by cam phasing, where the valve timing is adjusted by changing the position of the driven cam pulley on the camshaft.

When maximum power is required by the engine, opening the exhaust valve later helps release the burnt exhaust gas completely from the cylinder. This creates a longer valve overlap, where exhaust gas leaving the cylinder helps draw fresh air in. In doing this, more oxygen rich air enters the engine, ready for the next compression stroke.

When maximum power is not required, opening the exhaust valve earlier only partially empties the cylinder, leaving the oxygen deprived gas in the combustion chamber, thus reducing fuel consumption and the emission of harmful NOx gases by reducing the combustion temperature.

VARIABLE VALVE LIFT (VVL)

This system varies the duration of the valve opening, allowing it to stay open for longer under certain conditions. Although VVL systems operate slightly differently to VVT systems, both systems are used to achieve the same emissions control and engine performance benefits.

This is done in a number of different ways, dependent on the specific system. While some systems will engage a higher lifting camshaft lobe that runs on its own follower that lifts both the valves further, other systems may use a different shaped cam lobe to hold the valves open longer. These can be shifted along the camshaft by engaging solenoids, when required.

COMMON FAULTS

Common issues with variable valve systems can be down to contamination of the oil needed for the operation of dephaser pulleys and wear and tear of the components. Oil galleries within the pulleys and actuators can get blocked up with sludge or debris. As the actuators and position sensors on both VVT and VVL systems are electronically controlled, wiring faults can also occur.

|

Related Articles Related Downloads |