Cooling

Engaging Efficiency-Viscous Fan Couplings

Despite being part of more than 960,000 vehicles in the UK, viscous fan couplings (also known as viscous or viscous fan clutches in the aftermarkt) are one of the lesser known products of the engine cooling system.

VITAL STATISTICS Viscous fan couplings are used on cars with inline engine positions, mainly rear wheel drive.

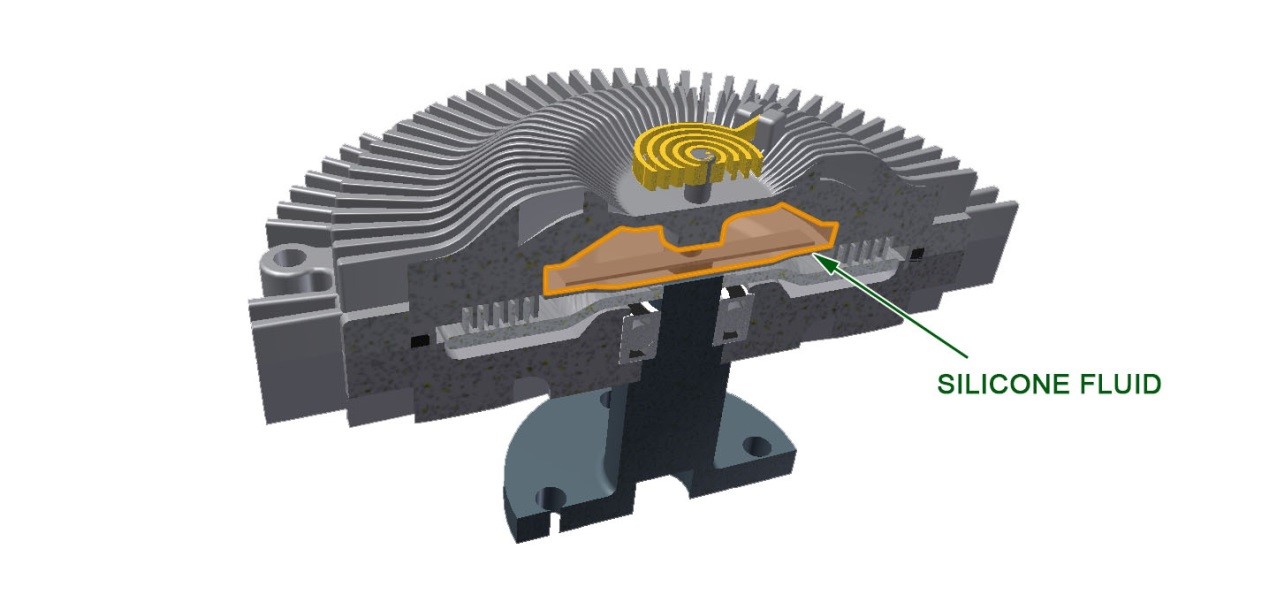

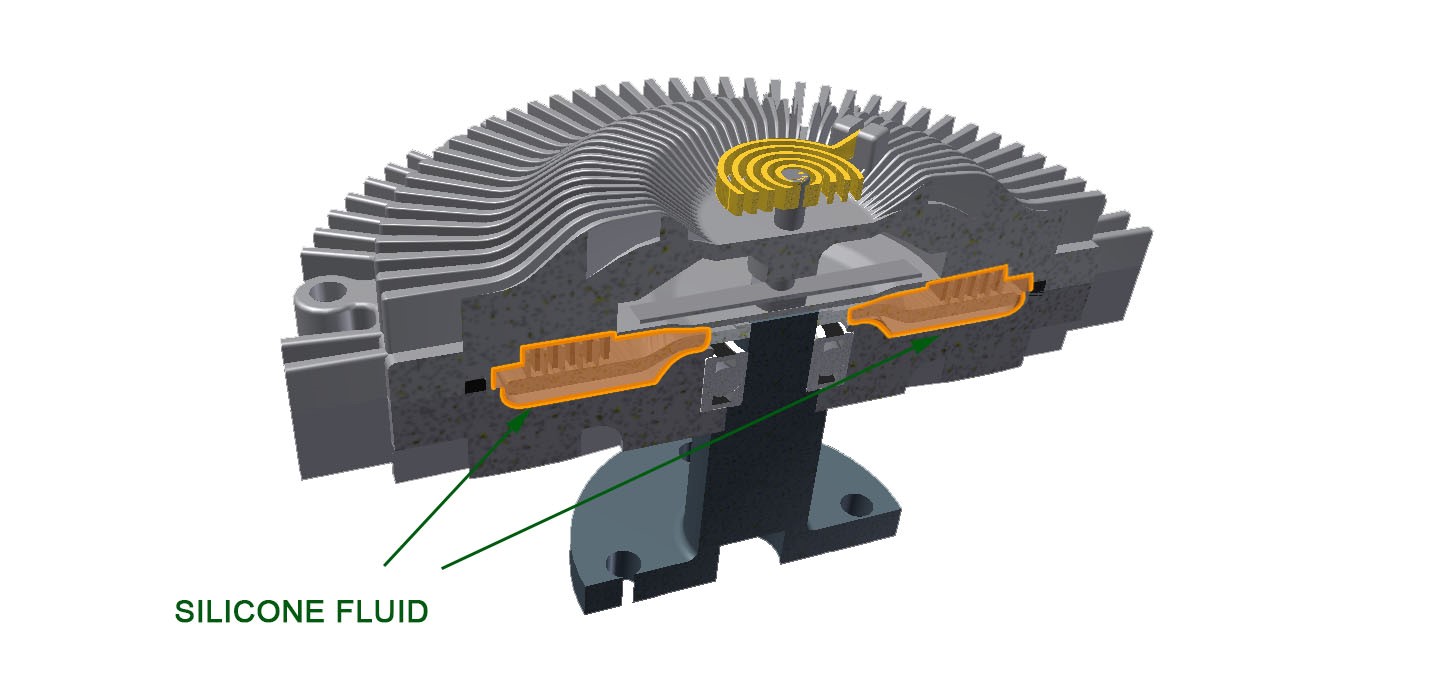

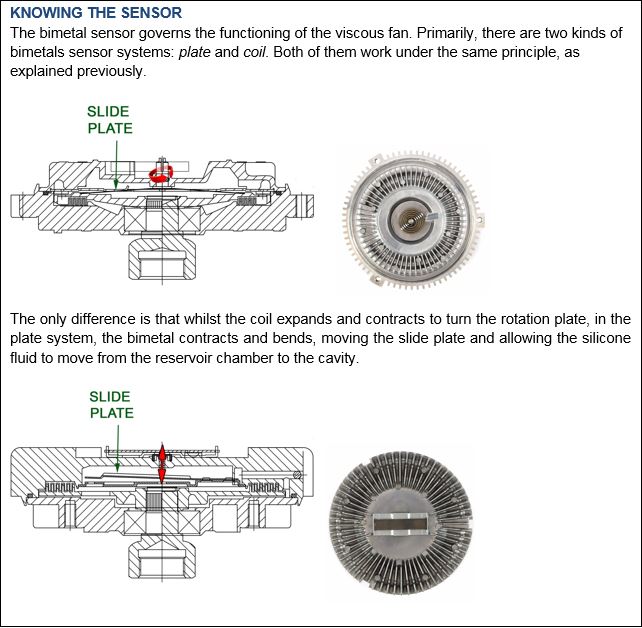

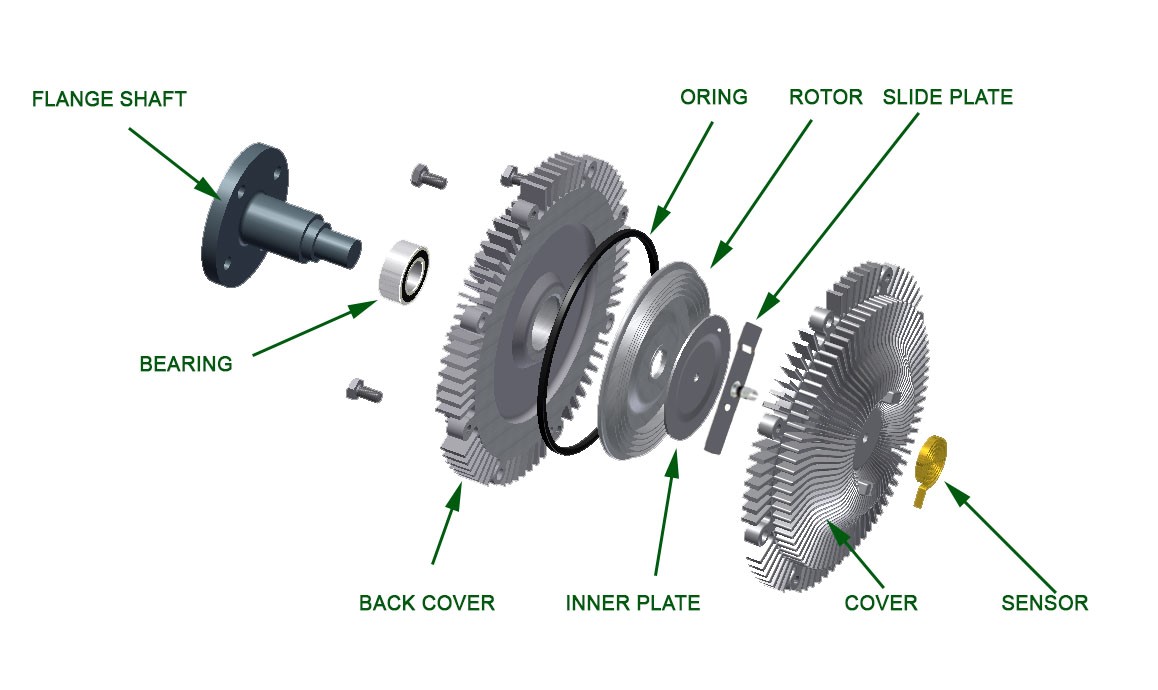

Function: · Controls fan speeds to aid engine cooling · Aids in the efficiency of the engine by engaging the fan, when necessary · Reduces load on the engine Assembly: Either assembled directly to a flanged shaft mounted on to the pulley of the water pump or threaded directly to the water pump hub. MECHANISM The mechanism of this product is based on the bimetal sensor located at the front of the viscous fan. This sensor expands or contracts, depending on the temperature imparted through the radiator. At cold temperature: The bimetal sensor contracts closing the valve, so the silicone fluid remains in the reservoir chamber.

At this stage, the viscous fan coupling is disengaged and turns at around 20% of the rotation speed of the engine. At operating temperature: The bimetal sensor expands, rotating the valve and allowing the silicone fluid to move through the entire chamber to the outer edges. This generates enough torque to drive the cooling fan blades at engine operating speeds and remain at a consistent temperature. At this stage, the viscous fan coupling is engaged and turns at around 80% of the rotation speed of the engine.

FAILURE It is good practice to always check the condition of the viscous fan coupling when the water pump is replaced, since a worn coupling will directly affect the water pump’s lifespan. A failed viscous fan coupling can stay stuck in the engagement position meaning it will always run at 80% of the engine rotation speed, can cause noise and vibration under high speeds and will increase fuel consumption. On the other hand, if the viscous fan coupling fails in the disengaged position, it will not draw air through the radiator, thus directly upsetting the cooling process of the engine. Common causes of failure include: · Leaking silicone fluid, disengaging the fan coupling · Bimetal sensor losing its properties due to surface oxidation, causing the coupling to be stuck disengaged · Bearing failure can occur if the viscous fan coupling has not been replaced after high mileage and the condition of the blades has deteriorated Best Practise When replacing the water pump, it is best practice to check that the viscous fan coupling is operating correctly as well. This part could be overlooked during the replacement of the water pump. The vehicle owner potentially would have to pay a second labour charge to replace the coupling at a later stage and a sales opportunity could be missed. |

Related Articles Related Downloads |

Location: Between the water pump pulley and the radiator

Location: Between the water pump pulley and the radiator