Cooling

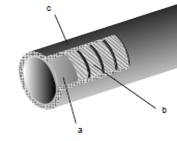

Cooling Hose Troubleshooting GuideAlthough hose applications have changed over the years, basic hose design has not. Hoses consist of three parts:

The tube conveys the coolant, and the reinforcement prevents the tube from rupturing under pressure. The outer cover protects the entire hose assembly from harsh external environments and contaminants. These three components are bonded together by special adhesives.

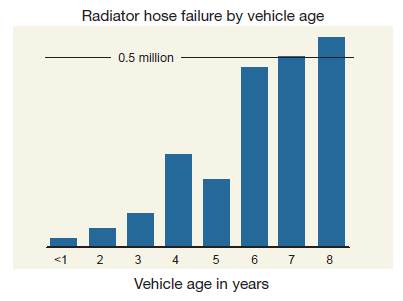

Pay special attention to hoses that have been in operation for four or more years; failures increase dramatically after that period (see chart). The best advice is to suggest replacement every four years for most vehicles. Vehicles operating under severe conditions may require more frequent replacements. When replacing hoses, insist on high-quality Gates products. They deliver longer-lasting service for your customers and build a reputation of reliability for your shop.

|

Related Articles Related Downloads |

| Next page |

While basic hose design has remained relatively unchanged over the years, hose materials have improved substantially. Thanks to these improvements coolant hoses last longer today than before. Of course, they can still fail, and when they do so, they usually fail from the inside. As there is no way to tell from a simple visual inspection if a hose has internal damage, Gates recommends that all cooling system hoses should be inspected at least once a year for damage from the major hose enemies: electrochemical degradation, heat, oil, abrasion, ozone and leakage.

While basic hose design has remained relatively unchanged over the years, hose materials have improved substantially. Thanks to these improvements coolant hoses last longer today than before. Of course, they can still fail, and when they do so, they usually fail from the inside. As there is no way to tell from a simple visual inspection if a hose has internal damage, Gates recommends that all cooling system hoses should be inspected at least once a year for damage from the major hose enemies: electrochemical degradation, heat, oil, abrasion, ozone and leakage.