Engine Management

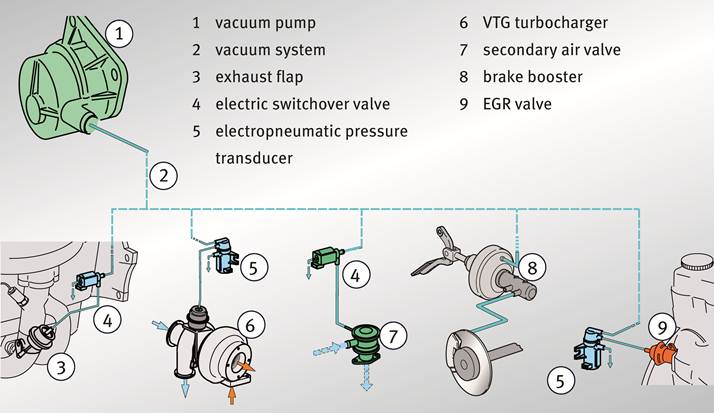

Vacuum Pump TechnologyThe vacuum pump is an essential component that is often overlooked. Pierburg explains the importance of this hardworking component. In the confined space of the engine bay it is often difficult to equip each component with motors powerful enough to operate them. Pneumatic actuators, powered by vacuum pressure, can supply the high actuation force needed to control components such as:

Brief Overview

The pump generates a negative pressure of between 750 and 850 mbar (10 to 12 psi) by drawing air out of the vacuum system. The pump works through positive displacement to move air from the vacuum system and then through the crankcase ventilation into the air intake system. Early designs of the vacuum pump include piston or diaphragm pumps which were driven by the camshaft. Modern engines use vane pumps. These are mostly fitted to the end of the camshaft and are supplied with lubricating oil from the engine’s oil circuit. In some vehicles the vacuum pump is combined with the fuel pump to create a ‘tandem vacuum fuel pump’. Critical Components In providing power for the actuators, the vacuum pump is essential to the workings of a number of safety critical and emissions-relevant systems. Brake booster failure can lead to hazardous situations – while the brake will still work the driver will have to manually provide the full braking force. The brake booster can increase the applied force by up to 5 times! The vacuum pump is therefore a safety critical component. As an essential component in the operation of the EGR system, the vacuum pump helps to reduce tailpipe emissions. With regulations becoming ever stricter it is critical that the vacuum pump is operating correctly. Fault Diagnosis

Common symptoms include:

Do not forget that the vacuum pump is part of the oil supply circuit, and that damage caused to the engine may result in contaminants entering the oil system. Vacuum pumps require an oil supply flow rate of 30-60 litres per hour. If foreign matter does enter the system it will damage the vacuum pump. When garages request parts to repair engine damage you should advise them to replace the vacuum pump too. This will help to prevent any consequential damage following engine repair. Pierburg is the leading European manufacturer of vacuum pumps .The range contains over 70 references covering a wide range of applications. |

Related Articles Related Downloads |

Vacuum pumps are used in vehicles where the necessary vacuum cannot be generated by the intake manifold, for example, direct injection and turbo engines with variable valve timing.

Vacuum pumps are used in vehicles where the necessary vacuum cannot be generated by the intake manifold, for example, direct injection and turbo engines with variable valve timing. The vacuum pump supplies so many different components that fault diagnosis can be difficult. So how do you identify vacuum pump failure?

The vacuum pump supplies so many different components that fault diagnosis can be difficult. So how do you identify vacuum pump failure?