Engine Management

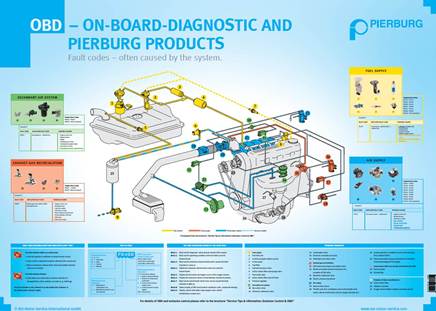

OBD and EOBD Systems ExplainedStatistically, every passenger car manufactured in Europe contains 3.2 Pierburg components, the majority of which are monitored by the on-board diagnostic system (OBD). The OBD system is a device that detects records and displays errors which occur in exhaust gas relevant systems. The intention is to prevent severe damage to engine components and reduce the negative impact on the environment. When exhaust gas relevant errors do occur, this is indicated by the malfunction indicator lamp (MIL). Activation occurs according to specially defined requirements and will flash if errors, such as a misfire, occur that would lead to cylinder shut-off or cause damage to the catalytic converter. Setting the standards EOBD was introduced in January 2000 in response to EURO III emissions standards and applies to passenger cars and light utility vehicles with petrol engines. As of 2003 it also applies to passenger cars with diesel engines. Legislation does not specify the methods of monitoring a module or component. This can be done in different ways depending on the manufacturer. What is important is that the module is monitored, with the system checking for:

The introduction of EOBD has produced the following consequences for vehicle manufacturers:

There is often confusion as to the use of the different terms such as OBD and EOBD. A distinction must be made between the respective exhaust gas standards and the laws governing on-board diagnosis. OBD I and OBD II refer to the American requirements for a diagnostic system. EOBD is the European version of the American OBD II. Euro I to Euro VI emissions standards (also referred to as EU I to EU VI) form the legal requirements for emission control in the European Community.In the American OBD II, the exhaust gas recirculation system (EGR) is monitored for its functioning and effect. In EOBD the system monitors the functioning but not its effectiveness (the same is true of the secondary air system). It is important to note that various vehicle manufacturers do supply vehicles to the European market that comply with OBD II standards.

Diagnostic connection The diagnostic socket (also known as the “CARB socket”) in the vehicle is the interface between the OBD system (engine control unit with fault code memory) and the workshop scan tool. Both the connection and the data transfer are standardised, making the plug assignment and protocol the same for all manufacturers. This makes it possible to read the fault code memory from vehicles of different manufacturers using just one OBD-compatible scan tool. The diagnostic socket is installed inside the cabin in a location that is both easy to access and protected from accidental damage. It has 16 pins, and seven connections are used by the EOBD. The remaining connections can be used by vehicle manufacturers for other purposes. The diagnostic concept In OBD it is not the quality of the exhaust gas itself that is checked, but rather the function of exhaust gas relevant components. When there is a malfunction, diagnosis is made easier by reading the fault code, but it is not always the case that a component indicated by the scan tool is actually faulty. The actual cause may be attributed to any one of a number of different components. Diagnosis therefore requires the expertise of a specialist with knowledge of the system. To help support the aftermarket, Pierburg has produced extensive technical material describing the OBD system and the relevant components. |

Related Articles Related Downloads |