Ignition

Ignition Systems of the FutureIgnition Innovation For almost 100 years the spark plug has been at the heart of the petrol ignition system and innovation has revolved around enhancing existing technology. This could change as vehicle manufacturers vie to develop more sophisticated ignition systems which provide better fuel economy and cleaner emissions.

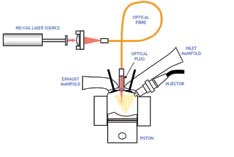

CARS WITH LASER BEAMS For the last 2 years Ford Motor Company and the University of Liverpool have been working on a project, which if successful will put laser ignition at the heart of the next generation of Ford direct injection engines. Replacing spark plugs with lasers enables greater control over the combustion process because laser ignition (LI) ignites the air-fuel mixture anywhere in the combustion chamber. In the LI engine, a laser beam is fired into the combustion chamber at the moment of fuel injection. The heat from the laser is sufficient to ignite the air-fuel mixture, and the beam can be split into multiple streams so multiple ignition points can co-occur, making the ignition process more efficient. As combustion is more stable in the LI system, less fuel is required for each combustion event giving better fuel economy and cleaner emissions. Comparatively, spark ignition (SI) is much more limited as it can only ignite a small volume of the air-fuel mix immediately next to the spark plug. Combustion then expands through chemical reaction to the rest of the cylinder. If the air-fuel mix is not in the right position, relative to the spark plug, fuel ignition does not occur at its optimum effectiveness, resulting in poor performance and high emissions. The LI project aims to help achieve reductions of 50% or more in hydrocarbons, carbon monoxide and nitrous oxide emissions. Researchers behind the project claim that the reason for this is that LI gives a better cold-starting performance and a ignition from a leaner fuel mix than SI. In Ford’s system, the laser can be reflected back to give the ECU information on what is happening in the combustion chamber – this will help to control air and fuel input in order to optimise performance. THE BEST OF BOTH WORLDS The main rival to Ford’s LI system and likely to hit the road much sooner, is Vauxhall’s Homogenous Charge Compression Ignition (HCCI) system. Run on petrol, the HCCI engine heats the air-fuel mixture to the point of auto-ignition producing efficiency of a diesel engine with the performance and low emissions of a petrol car. HOW DOES IT WORK? • Fuel is injected into the combustion chamber through injectors mounted on the cylinder head • Air is drawn into the combustion chamber through a separate valve • By the end of the intake stroke air and fuel are homogenously mixed • As the piston rises for the compression stroke, the volume of air is decreased through compression • Compression causes the temperature to rise to the point of combustion • Combustion occurs evenly through the combustion chamber HCCI has a high proportion of air to fuel (a lean mixture), so less fuel is need. Vauxhall claim the prototype Insignia HCCI returns a 15% increase in fuel economy compared to the SI version. Particulate matter and NOx emissions compared to traditional diesel are also significantly reduced (figures not yet available). HCCI has the efficiency of diesel without the expensive exhaust system with the attendant components such as particulate filters and urea injection systems. Heat is a necessary enabler for the HCCI ignition system. Consequently a spark plug is needed to initiate combustion when starting from cold. Vauxhall’s HCCI incorporates SI for cold starting and acceleration and the engine switches seamlessly between the two. HCCI is not a new idea but development for automotive applications has been stalled by the difficulty of controlling the combustion. Heat and pressure are necessary enablers for the HCCI process and as they are subject to constant and instantaneous change, they are very difficult to predict and control. Air temperature, atmospheric pressure, engine load and road speed also affect the HCCI combustion in a way that does not exist with either SI or LI. Individual cylinder pressure sensors, variable hydraulic valve lift and electro-mechanical phasers for camshaft timing are all essential components if the HCCI system is going to work and they must work together seamlessly and ceaselessly. Such technologies which were not available in the early days of HCCI development. Furthermore, the high pressure that is created in the engine means the materials used for bearings, piston crowns, head gaskets and even engine blocks have to be able to cope with higher pressure or the operating conditions of the HCCI engine will be severely limited. While Vauxhall seem to have overcome these obstacles, the challenge of making it affordable to the general public remains an obstacle. While exciting, it is not yet clear when either of these innovative new technologies will become full production realities. Ford’s LI project has only just exited phase one and has not yet been tested in a road-ready prototype. Vauxhall had scheduled the release of the HCCI version of the Insignia for 2012. In the meantime the spark plug remains the beating heart of the petrol engine’s ignition system. |

Related Articles Related Downloads |